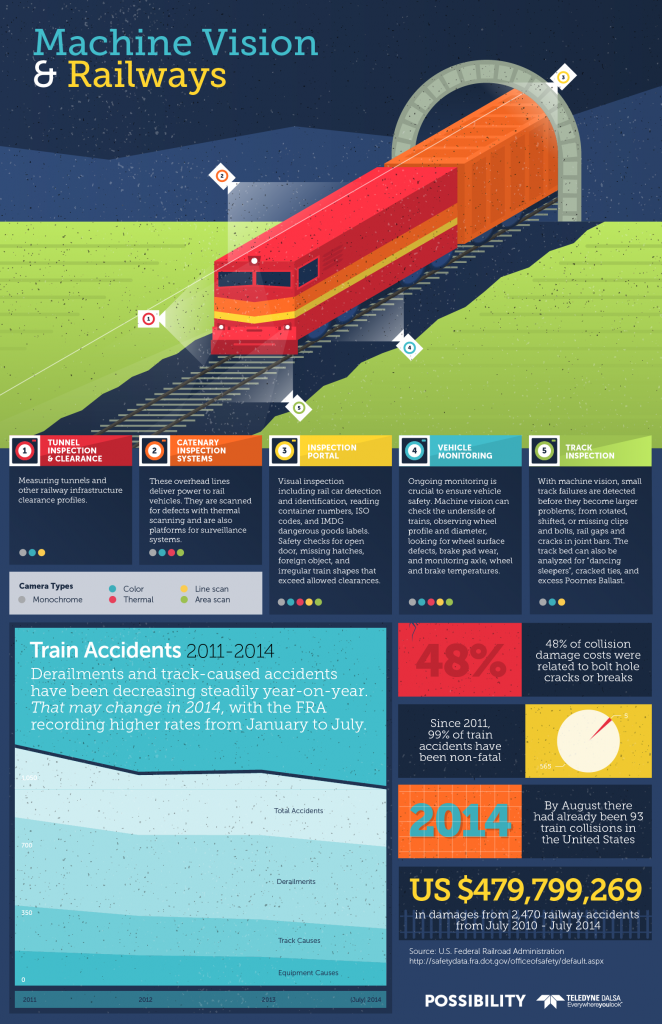

Infographic: Machine Vision and the Future of Rail Safety

The $480 Million Question: How to Reduce Train Accidents?

The call for safer railways

The disasters at Lac Megantic and the Bronx Metro-North, together causing 51 deaths, inspired urgent calls for improvements in rail safety. Investigations into both accidents found that they were largely preventable, casting a spotlight on the need for more effective safety inspections and practices. In the aftermath of the Bronx derailment, two U.S. senators have pushed for the Federal Railroad Administration to require the installation of video cameras on all trains to record drivers, unsafe track conditions, and any accidents that may occur. Closer examination of trains and railway track conditions for damage is crucial for railway safety and preventing further catastrophic failures.

[Click infographic to expand]

Automated inspection means better efficiency

According to the U.S. Federal Railroad Administration Office of Safety Analysis, track defects are the second leading cause of accidents on railways in the United States. Why? Historically the rail industry has inspected their equipment’s condition through manual inspection processes. These types of inspections are time intensive, expensive and fail to meet the quality and coverage needed to consistently reach high safety standards.

In the case of Lac Megantic, investigations into the incident found 18 key factors that led to the disaster, including corners cut to stay within a strict budget and a track that was in dire need of more frequent inspection. For the rail industry, which faces increasingly tight margins, this is a fundamental challenge. Often inspection requires equipment to be taken out of service, costing money and time while still falling short in terms of quality and scope.

An end-to-end real-time view of safety and performance

Machine vision technology offers an answer. The technology provides an automatic monitoring system that can record and report the conditions of the trains, tracks, and infrastructure in detail using multiple imaging techniques. Examining rail tracks, locomotives, and rolling stock for flaws and compliance can improve railway safety, reliability, and service quality.

This makes automation of inspection processes a massive opportunity to improve the quality and speed of inspection while reducing overall cost. Machine vision technology for Intelligent Traffic and Transportation Systems offers the potential to quickly and automatically monitor, assess, record, and transmit detailed information regarding the condition of railroad equipment undercarriages and components. Multiple imaging techniques allow the recording of both visual and thermal conditions.

A First Blueprint for Machine Vision: Look, Record, then Perfect

A First Blueprint for Machine Vision: Look, Record, then Perfect  Aerial Imaging: I Fly with My Little Eye

Aerial Imaging: I Fly with My Little Eye