Beyond sight – See it all with non-visible and multi-spectral imaging

Different wavelengths of light change interact with the world in different ways, opening up different practical applications

What is light, anyway? Thanks to the work of generations of scientists we know that light itself comes in waves. No, not rip-curls or rollers: electromagnetic waves with frequencies ranging from below one hertz to above 1025 hertz, corresponding to wavelengths from thousands of kilometers down to a fraction of the size of an atomic nucleus.

This frequency range (the electromagnetic spectrum) is divided into separate bands based on wavelength, and the electromagnetic waves within each frequency band are called by different names. The waves also have different characteristics, such as how they are produced, how they interact with matter, and most importantly for us, their practical applications.

In this article we’ll look more closely at those frequency bands and discuss the practical imaging applications for each: what we can “see” when we look with different wavelengths, and why we can see it.

The Spectrum

The frequency bands in the electromagnetic spectrum range from x-rays at the low end (the shortest wavelength) to long-range infrared at the high end (the longest wavelength). Let’s start with a quick overview of each band.

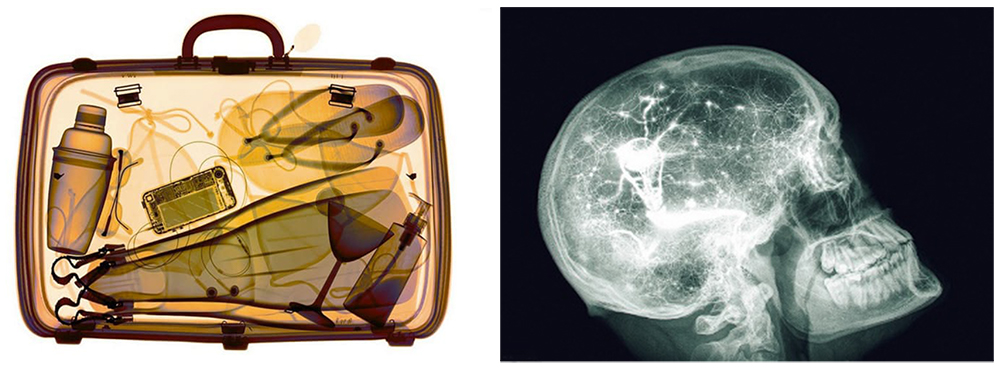

See deeper with x-rays

X-ray light passes through an object and gets absorbed according to the object density. We can measure that absorption to look at bones and other finer structures (such as luggage at the TSA check).

Feel the light with ultraviolet

We all know that certain types and intensities of ultraviolet light can cause sunburn. High-power UV sources are also used to locate and identify bodily fluids like blood, semen, and saliva, and to illustrate unsanitary conditions in hotels or restaurants. Even freckles are more prominent under UV.

See it all with visible light

Visible light is, well…visible. You can see it using external light sources such as the sun or artificial light.

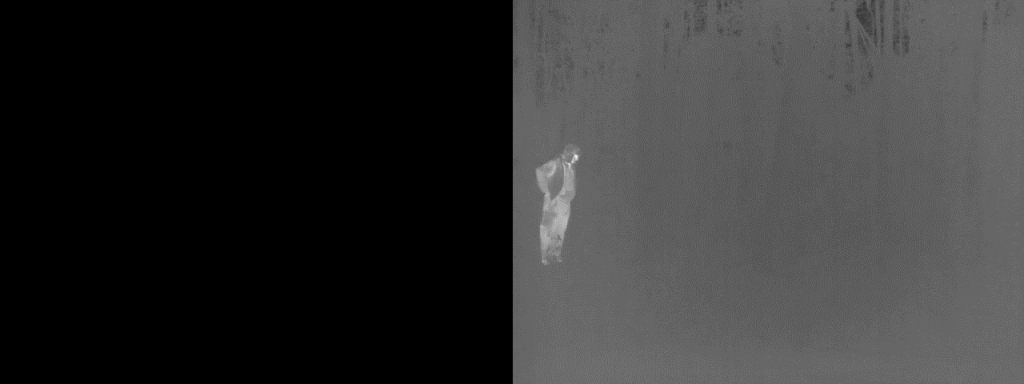

See in the dark with near infrared

The near infrared spectrum lets us see well in low-light conditions, using heat and moisture as catalysts. You can see from the darkness of the water in this image that water absorbs infrared light very well.

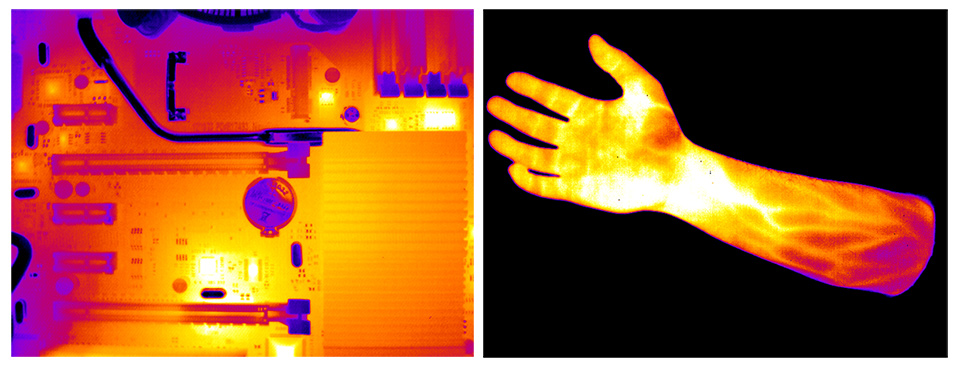

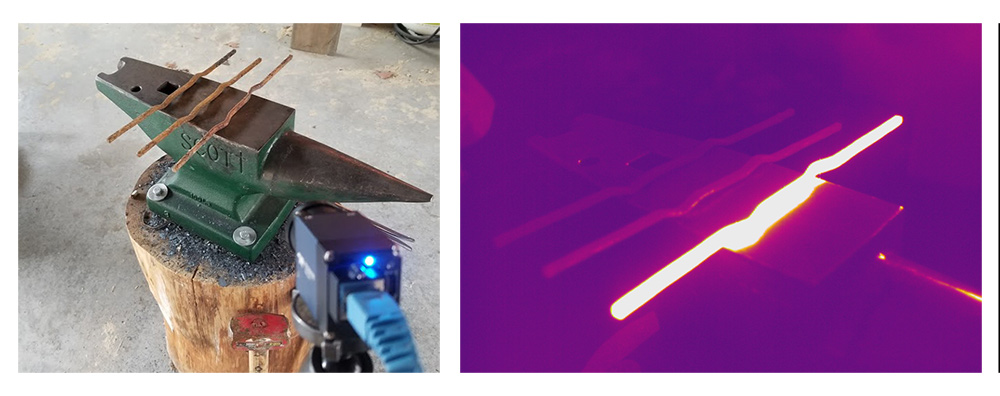

See the heat with long-wave infrared

With LWIR the signal doesn’t come from scattered, reflected and absorbed light, but from the object itself. The result is a per-pixel map of how the heat is distributed, allowing you to “see” heat.

Applications for Long-Wave Infrared Imaging

Long-wave infrared (LWIR) starts at around 5,000 nanometers and runs as high as 40,000 nanometers. At this length, the wave is less affected by ambient light and is mostly modulated by heat. When we turn our faces to the sun it’s the LWIR light that warms us. But did you know that just about everything is like a little sun, emitting its own heat? And until that heat becomes, well, hot, we can only detect it using LWIR.

Detecting the heat

In Teledyne’s cameras, the detector we use to see this heat is called a microbolometer. It’s a little resistor that hangs in a vacuum, warming up as it absorbs IR light. The graph below indicates the immersivity and irradiance per wavelength of an object based on its temperature.

Each curve in the graph corresponds to a “black body” object: an object that will absorb all the light that hits it. They look dark and matte to the eye and set the baseline for thermal (heat) imaging because we know the exact spectrum that black body objects emit according to its temperature. This allows us to determine from the signal the theoretical temperature of the black object, from which we extrapolate the absolute temperature measurement of the object in the scene.

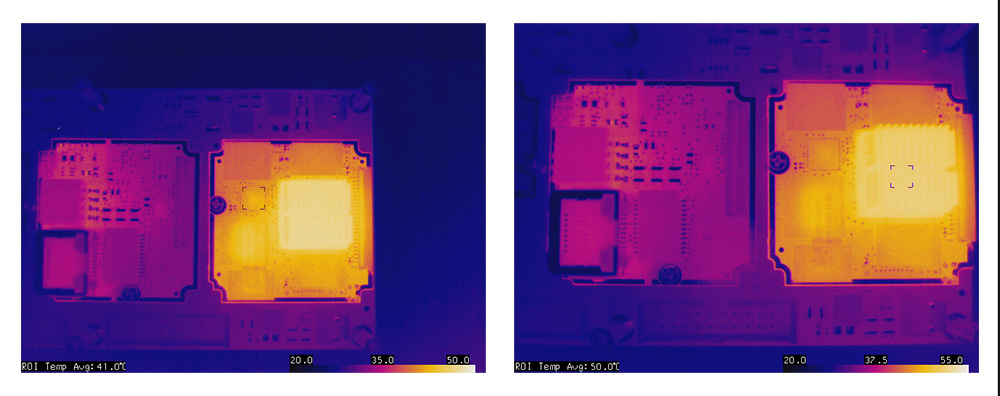

LWIR is useful for both thermal imaging (seeing things based on the heat they emit) and thermographic/radiographic imaging (detecting a specific temperature or temperature range in an object).

Seeing the hot things with thermal imaging

Thermal imagery lets you see in perfect darkness, see through fog or smoke, and easily detect life (hot) in ambient (cooler) surroundings. It can also be used to monitor processes where heat distribution is important.

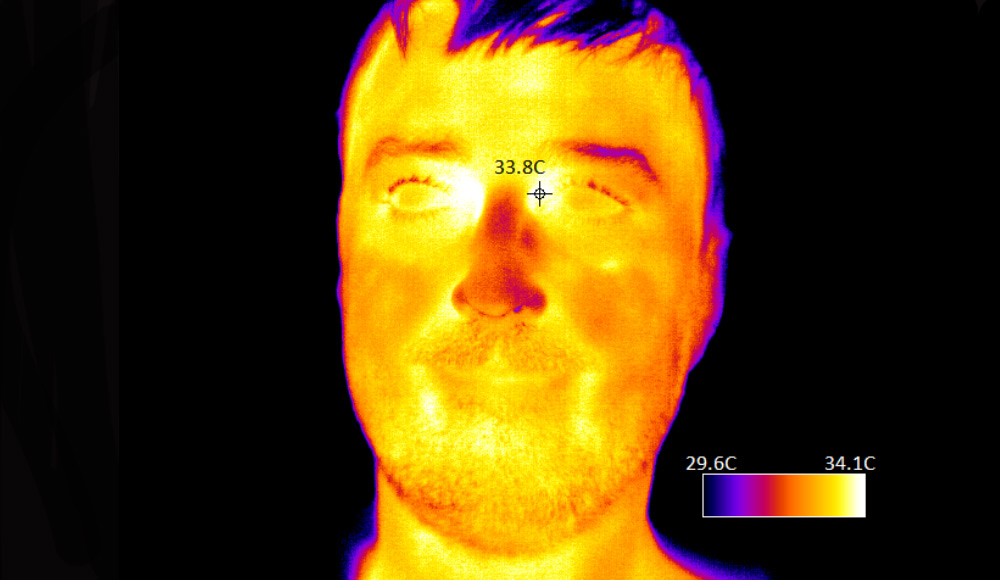

Taking a temperature with radiometric cameras

Seeing heat is great, but sometimes you need to know exactly what the temperature of an object is to prevent damage, avoid contamination, and more.

Another very timely application of testing absolute temperature is COVID-19 testing. We see a very high demand now for extremely accurate measurement – plus or minus .3 degrees – and radiometric LWIR cameras can help with that.

Accuracy in these cameras comes down to reference: place a reference in the image for which you know the exact temperature, and the technology does the rest.

Teledyne and LWIR

Teledyne’s legacy LWIR camera is the DXM640, which uses the 640×480 ULIS third-party sensor and offers shutterless imaging for better image quality.

Our flagship camera based on our own microbolometer technology is the DALSA GXM series, offering very high dynamic range. Our newest model is optimized specifically for measuring skin temperature.

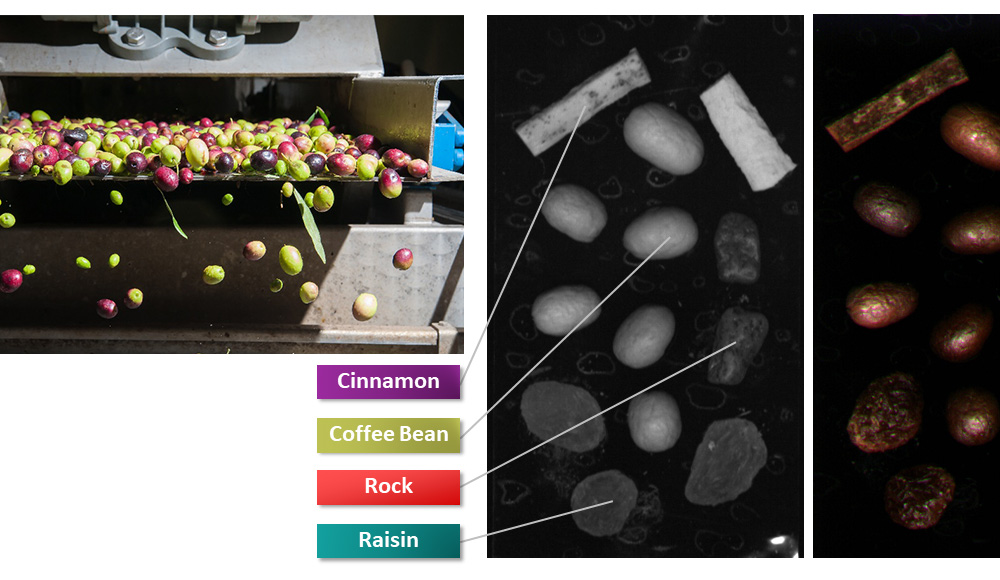

Short-Wave Infrared Applications

Short-wave infrared (SWIR) is light in the 900 to 2,500 nanometer range of the EM spectrum. Not visible to the human eye, SWIR can detect and highlight certain features that are difficult or very impossible to distinguish with visible light and visible cameras. Teledyne’s Linea SWIR line scan camera can help with that. Applications like food sorting, ensuring fill lines in plastic containers, (like laundry detergent) and detecting microcracks in solar panel inspection can all benefit from imaging in the SWIR.

Seeing through to the other side

SWIR can help us differentiate between similarly colored objects, see objects with very high temperature, and even see through some materials.

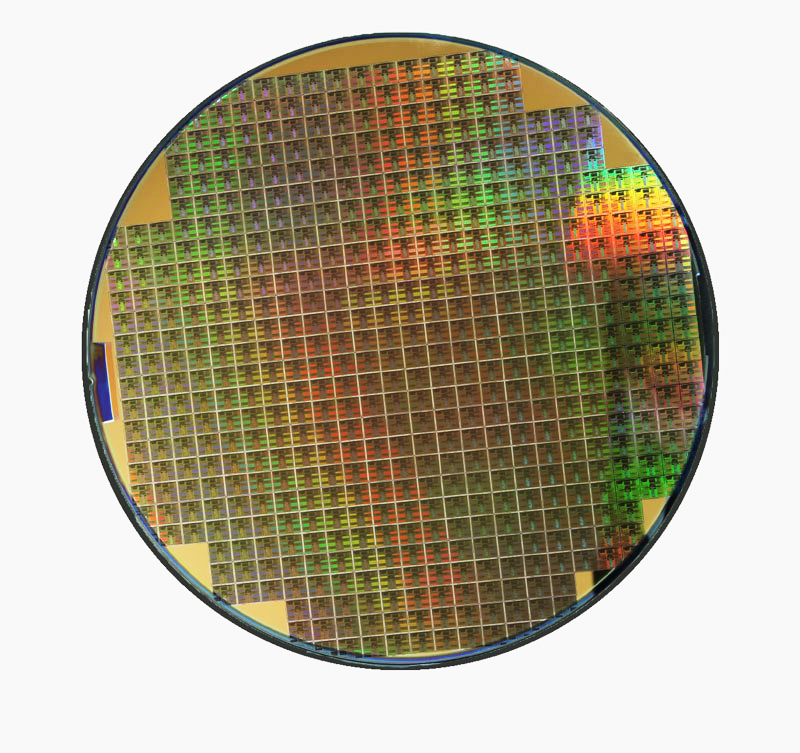

SWIR light passes through silicon at around 1,140 nanometers. In the lab example below, we taped a target to the other side of a silicon wafer, but that didn’t stop our LINEA camera.

Sorting the wheat from the chaff

At around 1,450 nanometers moisture shows up as very dark, allowing us to, for example, detect fill levels in opaque containers. Moisture is also present if fruit is bruised, SWIR lets us see it well before our eyes can detect it.

Near Infrared

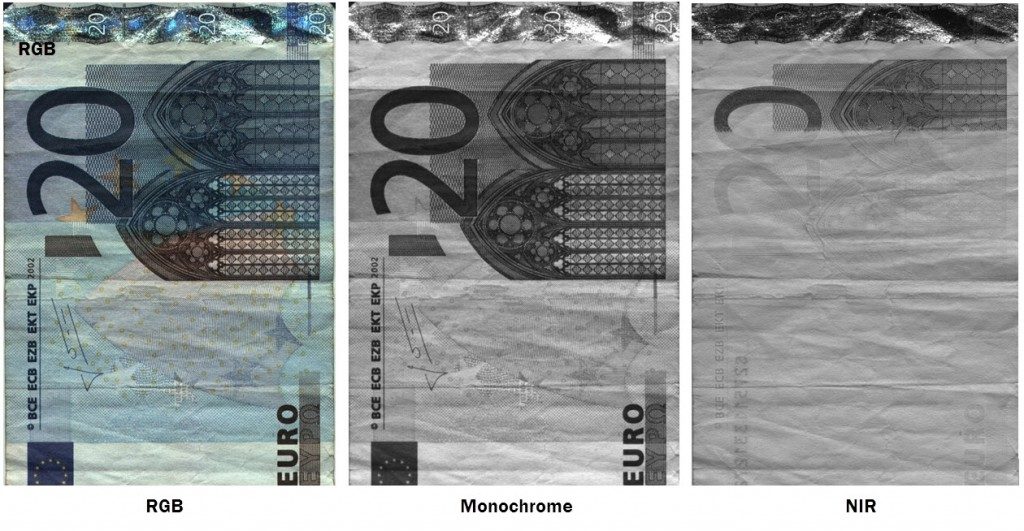

At 700 – 900 nanometers, near IR is often seen as the transition stage to SWIR, with slightly more accessible technology. As it is just above the visible spectrum, Teledyne has combined the two on our sensors and cameras for many years, including the Piranha4 Multispectral line scan series, Genie Nano, and LINEA ML.

When color is not enough

With the combination of RGB and near IR you often get an all-in-one solution that can help you identify invisible features along with visible features all in a single pass. One case where invisible security features are important is money.

The crops are asking for help

Efficiency in agriculture is critical: high yields = high profits, and when disease strikes, the sooner you know the better. Near IR can detect changes in how the plant reflects light, which is a leading indicator of plant health, well before any signs of disease are visible. That means more broccoli for everyone!

Visible Light Applications

At 400 – 700 nanometers, the visible spectrum is the workhorse for optical inspection, with most imaging done in this range. While we can see the visible spectrum with our eyes, cameras don’t get tired, bored, sick, or distracted.

Advanced filters show all the angles

With advanced filter technology in the LINEA HS Multifield, objects can be captured with light from different angles in a single pass, critical for defect detection. The filters also almost completely eliminate cross-talk – one color bleeding into another and interfering with the image.

Light is a polarizing subject

In machine vision, polarization can be used to detect physical properties such as birefringence, stress, depth, and more. The technology can be used in sorting foreign materials from cotton, foods, and other products where contaminants are identified by the change of polarization states in the optical reflection.

Ultraviolet Light Applications

One of the reasons why we can see some things in part of the spectrum and not in others is because different materials have different spectral properties. Materials that look very similar in the visible or perhaps even in SWIR may look very different in the UV part of the spectrum (10 – 400 nanometers).

Scatter matters

With UV we can see contrasts between different metals or plastics, and through a property called scattering we can use UV to detect defects or contaminants much smaller than visible with regular optical imaging.

UV light comes in three flavors: UV-A, UV-B, and UV-C, each progressively higher in energy.

X-ray

X-ray is not just for broken bones and tooth decay. Because X-rays – between 10 picometers and 10 nanometers – enable us to penetrate deep into materials without tearing them apart, they are ideal for non-destructive testing and inspection.

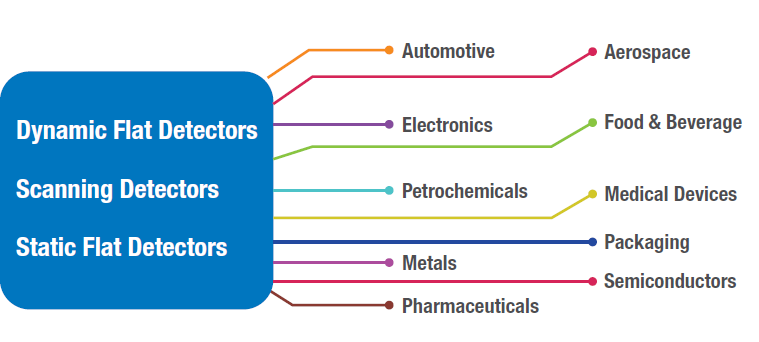

Seeing deeper means knowing more

From detecting contaminants in packaged goods to bombs in a suitcase, bones in produce, and blips in a battery, x-rays can be flat, scanning, dynamic…and often very large.

CMOS detection increases efficiency

Our x-ray technology leverages our CMOS detector technology, which offers better images at lower x-ray doses. That enables a wider dynamic range, better resolution, better contrast, and for customers higher speeds, longer lifetimes, and lower doses.

Look differently

Sometimes all it takes to see everything we need is to look differently. Different areas of the spectrum reveal different things, and our technology can help you shine a new light on your imaging challenges.

Want to learn more about imaging across the EM spectrum?

Watch this informative webinar presented by Product Managers Mike Grodzki and Jean Brunelle, where they highlight advancements in extra-visible imaging (X-ray, ultraviolet, shortwave IR, and longwave IR plus combinations), and the latest in multispectral filter technologies, including advancements in polarization, hyperspectral and multi-band imaging.

How Deep is your Light? Imaging Across the Spectrum

How Deep is your Light? Imaging Across the Spectrum  Infrared imaging applications: See the heat, feel the light

Infrared imaging applications: See the heat, feel the light