Inspecting Paper Rolls with Ingenuity

High-Speed Barcode Scanning and OCR with the help of Color TDI Imaging

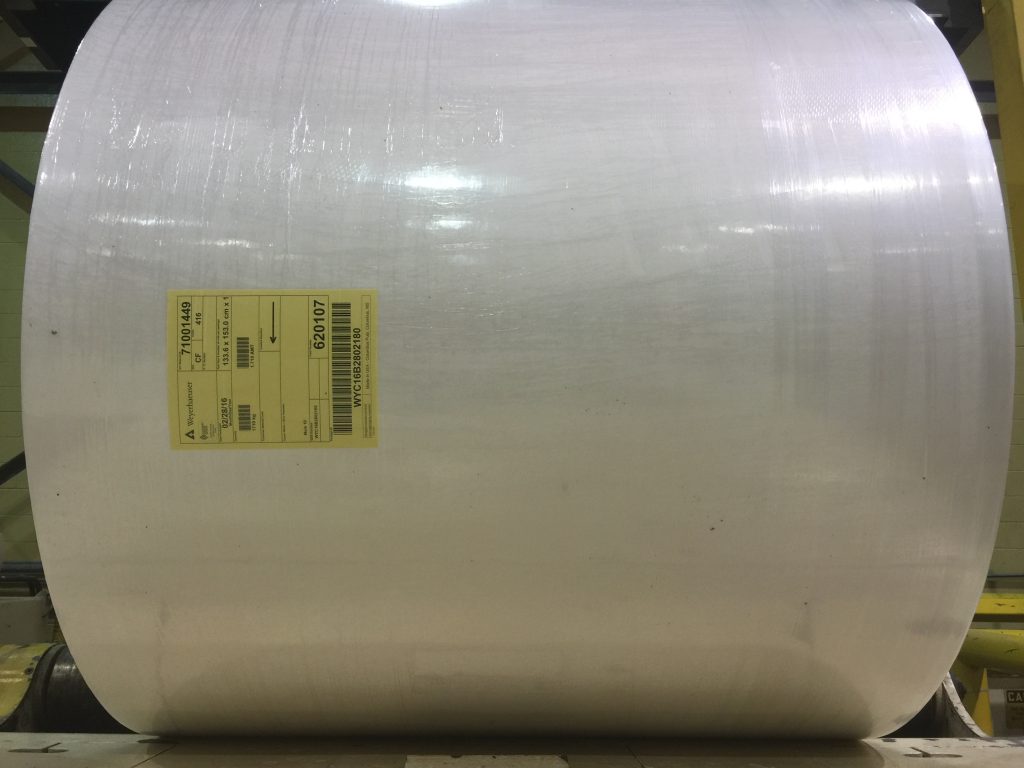

Integro Technologies, a turnkey machine vision system integrator, recently worked with a customer who had a very specific need: create a cost-effective and error free solution for the inspection of large rolls of shrink-wrapped paper.

Since 2001, Integro Technologies has been working with companies to develop superior quality inspection solutions. To do so, they use vision, robotics, and control systems designed to enable customers the ability to produce the highest quality product possible, whilst simultaneously reducing waste and increasing profitability.

When approaching this particular inspection challenge, Integro identified that a machine vision system of this scale would need to meet two goals. Firstly, the implemented system must be able to locate the paper labels attached to the rolls and be able to read the associated linear barcode on the label which contains critical information unique to each. In addition to the barcode information and the color of the label, the text on the label must be identified by performing Optical Character Recognition (OCR). OCR is the electronic recognition of printed or written text by a computer and can perform certain functions like product tracking.

Secondly, the system would need to be able to detect any small debris that may have adhered to the outer portion of the paper roll, or within the shrink wrap material in which the paper is contained, to ensure that only the highest quality products are delivered. The typical forms of defects that must be detected by the system include smudges, bugs, broken washer pieces trapped within the packaging, crown core pieces, pieces of pulp, rubber, paint and specs of dirt.

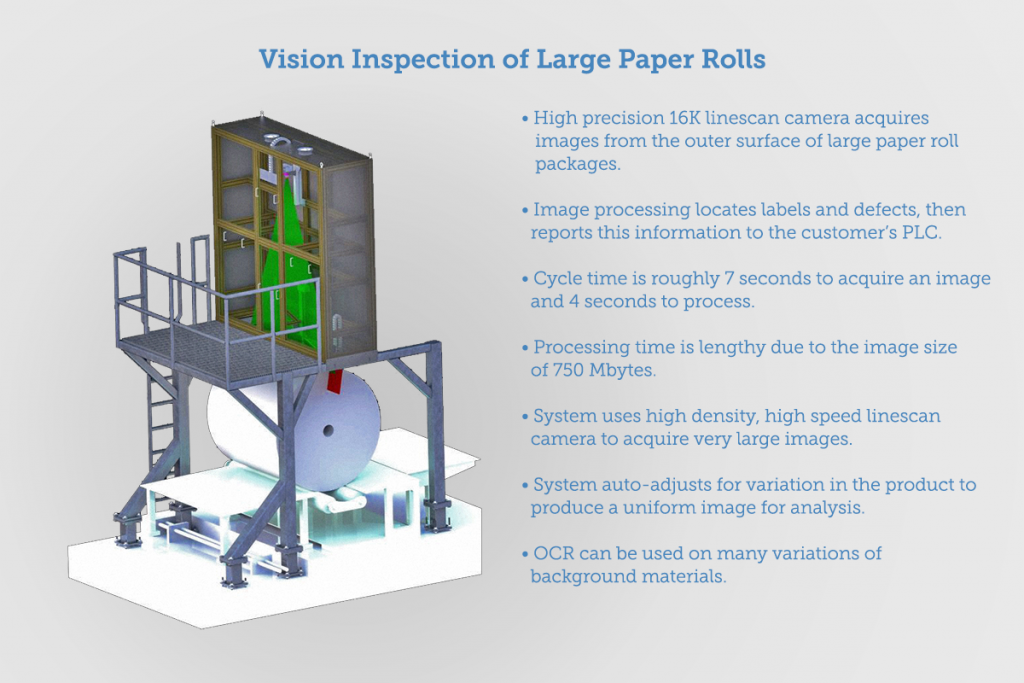

To rise to this challenge and meet the specific requirements of the customer, Integro utilized Teledyne DALSA’s Piranha XL Multi-line CMOS TDI color camera and an Xtium CLHS PX4 frame grabber. The Piranha CMOS camera provides an ideal solution to Integro’s inspection needs because of its high speed, high data throughput, and low noise features. Additionally, the camera’s time delay integration (TDI) feature is highly useful for Integro’s inspection system, due to the need for maximum sensitivity. TDI is a method of line scanning that permits greater scanning speeds in low light or at reduced lighting levels, and allows for the accumulation of multiple exposures of the same moving object, making it ideal for high-speed web inspections.

To carry out the inspection process, Integro triggers the inspection through the Xtium frame grabber from an encoder mounted to the shaft of one of the motor-driven rollers that rotate the rolls of paper below the camera. The sampling rate is 0.12222mm per acquisition. As the rolls rotate, the PiranahXL color multi-line camera acquires an image one line at a time to form a long image that is a linear representation of the outside surface of the roll.

One of the challenges Integro faced in implementing this sytem was in relation to lighting. A good and even source of illumination must be maintained during the inspection process, which can be difficult due to the varied diameters of the rolls of paper being inspected. To resolve this issue, Integro installed a moving light bar controlled by a ball screw actuator. This sytem has a distance sensor that helps to determine the height of the roll of paper being inspected. Once information on the height of the paper has been obtained, the light bar can then be moved to the correct position by adjusting the actuator to ensure the accurate inspection of that particular size of paper roll. This allows a consistent distance between the camera and the rolls being inspected at all times.

“The Teledyne DALSA PiranhaXL Multi-line CMOS TDI color camera was selected for its resolution, speed, and color requirements for this application,” said Cristina Fein, Project Manager at Integro Technologies. Given the success Integro has achieved with this machine vision system, they intend on using other Teledyne DALSA technologies for future applications.

Integro has had this custom machine vision system in place for more than a year, and has seen great benefits for their customers to date. By automating the inspection of paper rolls, their customer is able to deliver high-quality products and have eliminated the potential for human error by relying on machine vision for high-speed inspection.

A New Way: Automotive Fabric Inspection

A New Way: Automotive Fabric Inspection  A New Look: How Machine Vision Is Changing Textile Inspection

A New Look: How Machine Vision Is Changing Textile Inspection