Seeing the Unseen with Microbolometer Technology

Brian Benwell discusses the art—and science—of the possible with new, lightweight, uncooled infrared detectors

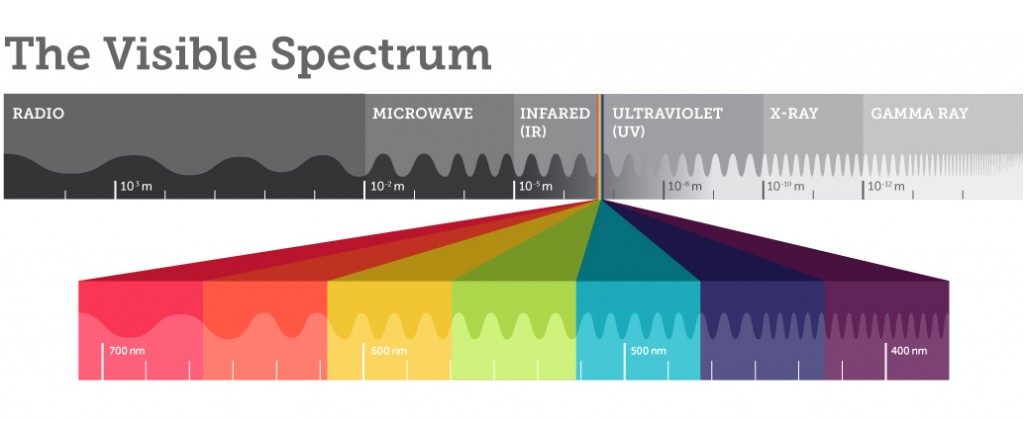

Human sight is an amazing gift. With it, the world appears in three dimensions and, for most people, our surroundings shimmer in over a million colors.

An estimated one percent of the world’s population can do even better. Individuals who are tetrachromatic, meaning they have an extra cone or receptor in their eyes to absorb wavelengths of light and transmit them to the brain, are capable of seeing dimensions and nuances of color—roughly 100 million of them—that are invisible to the average person.

Of course, for all that human eyesight gives us, it falls short in one important capability: we are not able to see very well, unaided, in the dark. We need only to trip over a family pet or be surprised by someone in the woods at night to be reminded of our limitation.

Our poor night vision can be explained in part by the lack of a tapetum lucidum, a layer of tissue that reflects visible light back through the retina to increase what’s available to the photo-receptors in our eyes. It’s what contributes to the superior vision of animals that hunt at night, for example, and some deep-sea creatures.

Yet there are times that we, too, might want—or need—to see objects obscured by darkness, or by thick smoke or fog. We are prevented from doing so by our natural abilities.

We’ve tried to compensate with technology. But until recently, the options available—particularly to consumers—were too unwieldy to be practical. Now that’s changing.

Turning Night Into Day

Uncooled long-wavelength infrared detectors based on Vanadium Oxide Microbolometer technology are opening new possibilities in a wide range of applications. The small, wafer-level packaging means that the IR sensor can be simpler and more reliable, while consuming less energy and costing tens of dollars instead of hundreds or thousands.

“Historically, thermal imagers were fairly big and power-hungry devices,” explains Brian Benwell, Program Manager at Teledyne DALSA. “Now they can be something that can move with a person that needs to see without visible light.”

Military personnel and civil first responders may be among the first to benefit from new and more affordable methods of seeing the previously unseeable, but everyday users from all walks of life will also soon enjoy routinely discovering what’s hiding from them.

Indeed, there are signs that it’s already happening. Consider the home improvement market: thermal cameras can pinpoint surface temperatures to help you find gaps in insulation and broken weather sealing—places where heat is escaping a building. Today such cameras are expensive, limiting their use to larger construction companies. But as they become cheaper through the use of microbolometer-based imagers, more and more DIYers will be able to use them for their own projects.

The automotive industry is another early adopter. The reason: uncooled infrared imaging offers a practical way to improve driver safety through night-vision systems in vehicles.

Thermal imaging will also become available on a more personal level. The FLIR One, for example, is an infrared camera attachment for the iPhone. “The real exciting thing there is that it basically enables people to see in the dark,” says Benwell.

How we see the world is about to change. And according to Benwell, that transformation will occur as a result of microbolometer technology. Whether it’s inside new, lightweight instruments that are easily portable, wearable or installed in places, “soon enough, it will be just another device that’s part of our everyday experience,” he predicts.

A Bright Red Future

The technology still has a way to go before its potential can be fully realized. For one thing, the sensors within the camera can only work when packaged under vacuum to isolate them from ambient heat. While the vacuum can be relatively well-sealed, it can still be compromised over time by off-gassing of the core elements. Most of today’s sensors have a larger vacuum cavity, and so the off-gassing takes longer to compromise the vacuum—in the range of 5-10 years, say. But for applications that need smaller and smaller sensors, the design and manufacturing of microbolometer-based imagers will have to advance to deal with these challenges.

Still, the promise is there. What more could you do with very precise thermal imaging? Could you tell if an electrical device was overheating or short-circuiting? Could a doctor measure a person’s blood flow? Will farmers be able to detect early signs of disease or infestation?

We are just beginning to see the possibilities.

When the Invisible Becomes Visible

When the Invisible Becomes Visible