What Hides Beneath: Securing Borders and Places

Comm Port Technologies' under-vehicle surveillance systems

Comm Port Technologies, based in Cranbury, New Jersey, USA has been providing technology-based security solutions to their customers for over two decades. Their product range includes multiple designs and models of Under-Vehicle Surveillance and Inspection Systems (UVSS/UVIS). In 2015, Comm Port introduced their state-of-the art CPAS UVIS to meet the growing need for securing premises by checking vehicles at points of entry.

Inspecting Vehicles for Explosives and Contraband

Throughout history, vehicles have been used as weapons – be it for a simple crime, or for perpetrating gross acts of terrorism. Therefore, the practice of inspecting vehicles for safety reasons, is not a new phenomenon. As far back as the 1940’s, there are documented instances of undercarriage checks of cars, vans, trucks, or buses. As a very rudimentary inspection system, a convex mirror would be mounted at the end of a stick and passed under the carriage to check for fugitives, smuggled contraband goods, and even explosives. However this method was fraught with limitations, not only because it provided a partial view of the underside of the vehicle, but more importantly because it offered the person conducting the scan no protection in the event of a concealed explosive device.

It was not until the 1980’s that undercarriage vehicle surveillance systems were developed using standard CCTV cameras capable of capturing monochrome images. Today, these inspection systems are readily available and can be identified by many of the following acronyms: UVI (under-vehicle inspection), UVIS (under-vehicle inspection systems), and UVSS (under-vehicle surveillance systems).

Under Vehicle Inspection Technology

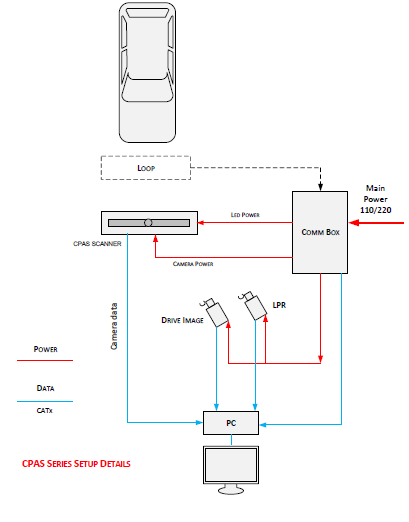

The UVIS market boasts two broad categories of systems – temporary mobile imaging units and fixed permanent systems. Fixed type systems are installed in a cavity below the surface of the road, whereas temporary configurations have the instrument embedded in a heavy-duty rubber strip or under a metal ramp at a checkpoint in the roadway. In either case, the approach is the same: a vehicle proceeds to drive over the imaging unit whereupon the cameras capture images or video of the undercarriage. These images are then transmitted to a control centre where they are reviewed by personnel from a safe distance. To help ensure complete traceability of a given vehicle, these systems work in conjunction with license plate readers (LPR) and driver image capture cameras to record all aspects as it enters and exits the facility. Once the undercarriage images are reviewed, compared, and verified, the vehicle is allowed to proceed or the driver is detained for further questioning.

The major challenge with UVIS’ is the ability to provide high-resolution images captured at driving speeds, with real or near-real time processing to avoid unnecessary and potentially unsafe delays in identifying threats. However, not all video camera solutions provide “stitched” video imagery, instead delivering multiple strips of video that require individual review for detection and inspection. These lower-resolution and non-stitched images are not sufficient quality for automated algorithms and cause delays and difficulty for security and inspection operators. As well, many systems require vehicles to move over the cameras at speeds as slow as 10km/hour, hampering the entry and exit of legitimate vehicles.

Employing the Best Tools for the Job

The Comm Port CPAS UVIS uses state-of-the-art color area camera technology to inspect the underside of vehicles or other equipment entering and exiting a facility. The cameras are looking for explosives, contraband or hidden compartments to ensure the safety and security of the facility and also act as a deterrent toward terrorist attacks and sabotage. It is a complete inspection system which consists of an area camera, monitor, industrial strength PC, LPR camera, driver image camera, LED lighting arrangement and all associated hardware and software modules. The camera is suitable for day and night operation and is capable of storing over 500,000 images. The CPAS UVIS has the fastest frame capture rates in the industry, with options from 500 FPS, 700FPS, 900FPS, and 1100FPS, so its loop-based sensors are able to dynamically and automatically adjust the image according to the speed of the vehicle. This enables it to capture a complete, high-resolution composite under-body image of any vehicle passing over it at speeds ranging from 1 to 75km/hour.

Teledyne Imaging’s Genie cameras form the backbone of the CPAS UVIS system, chosen for its superior technical qualities, but the key features that make it the camera of choice for this application include its:

- form factor: The Genie is small enough to build into the low-profile in-ground physical hardware configuration of the CPAS UVIS

- available lensing: It can accommodate a wide selection of lenses with different fields of view (FOV), which adds versatility to the CPAS UVIS

- high frame rate: The Genie’s frame rate can reach up to 900 FPS and in some cases, 1100 FPS, allowing the CPAS UVIS to operate at vehicle speeds in excess of 75km/hour without sacrificing image resolution or quality

- high resolution: The high resolution allows clear and accurate imaging and processing

- reliability: The Genie provides the necessary reliability for deployment in this highly sensitive application with low system failure or downtime

Comm Port approached Active Inspection to develop the image acquisition and processing software for their CPAS UVIS system. A provider of custom machine vision solutions and software development services, Active Inspection has been working with Teledyne DALSA to develop line scan and area camera inspection solutions for more than 20 years. They designed a custom algorithm for building high-quality composite images from a large sequence of acquired images in real-time. Important considerations Active Inspection factored in was the ever-changing nature of an outdoor environment and the ability to scale up and down for a variety of sized and shaped vehicles.

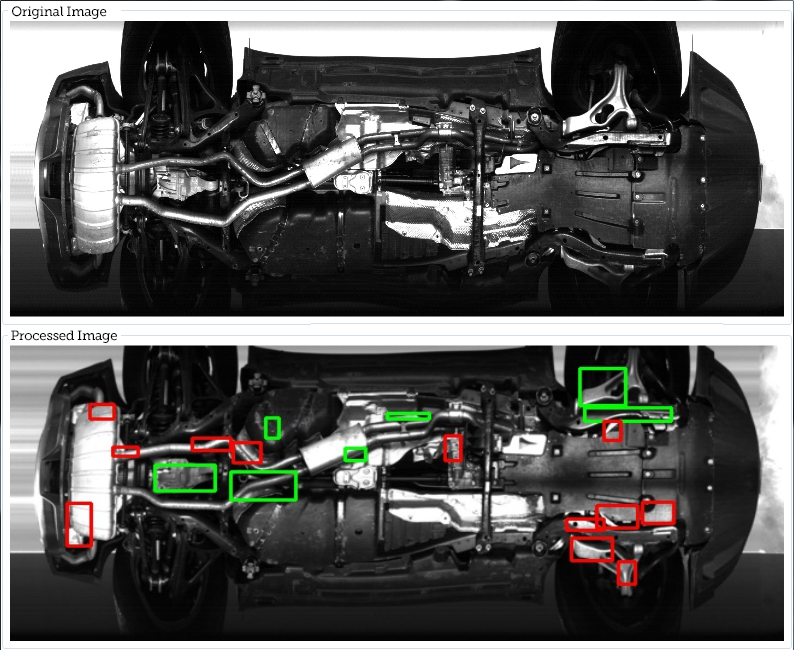

Flagging the Anomalies

The resulting efforts are what is now known as Comm Port’s Automatic Change Detection Module (ACDM), an advanced software technology that creates instantaneous image comparisons between vehicle pass imagery generated by the CPAS system and a reference image of the underside of the vehicle. It can be used for comparison of any image – whether identical, partially dissimilar, or substantially different. It is able to immediately detect variations and anomalies found in the undercarriage and flag them for further inspection.

Using Technology to Thwart Criminal Intent

“The challenge we have as a manufacturing company for the past 20+ years is to stay ahead of the technology curve while adapting to the changing threats and evolving needs of the multiple vertical markets we serve,” says Manny Patel, CEO – Comm Port. “In addition to our in-house research and development, and software teams, finding and working with key technology partners such as Teledyne keeps us in front of that market demand. Our technology partners allow us to consistently push the envelope in terms of the specification, performance, and flexibility of our product, which is something our customers appreciate and have grown to expect from Comm Port.”

Comm Port’s customers include high-security facilities such as diplomatic embassies, government offices, Department of Defence and military installations, prisons, law enforcement, and international border crossings. They are also active in securing the transportation and critical infrastructure market, having served customers in the airport, railroad, seaport and highway segments. Their products are also deployed in perimeter protection solutions for oil and gas facilities, mining and energy generation plants. “Soft targets” such as hotels, resorts, parking garages and sports arenas also form a large segment of their business. Currently, Comm Port has installations and customers on five continents and are in over forty countries.