How Thermal Imaging Can Help Prevent Wind Turbine Failures

Thermal imaging via aerial drones can be used for preventative maintenance on wind turbines, detecting failing components before they break.

When seen from a distance, wind turbines appear to be no bigger than large trees. Majestically turning their blades in the breeze, providing us with abundant clean and renewable energy.

But if you stand up close to a turbine, you realize that they are massive machines, often the equivalent of a 32-story building from the base to a blade at the apex of its rotation. The blades can be up to 120 feet long and move between 10 and 20 revolutions per minute. These majestic machines are serious business with each blade on the turbine costing up to a million dollars.

Thus, keeping turbines in good working order is essential for efficient energy production, but also the safety of anybody in a turbine’s immediate vicinity. If the blades of a turbine become damaged, or spins too fast because the brake or gear mechanisms are damaged, a blade can snap from the turbine and cause significant, life-threatening damage.

The old method of inspecting turbines involved a team of people climbing up the tower and dangling down the sides of the blades for manual visual inspection. The process could take three days to inspect one turbine, a period when the machine is not producing energy. These days the process is not so onerous with the combination of thermal imaging equipment and aerial drones allowing engineers to inspect a single turbine in less than an hour.

Wind Turbine Components Heat Up Before They Fail

A general rule for machines is that components will increase in temperature when they are about to break. For instance, a lightbulb will burn brightly for a moment before it burns out, or a photovoltaic cell will increase in temperature if it’s operating inefficiently. In a machine with moving pieces, increased friction creates heat that could be the first sign that a part is about breakdown.

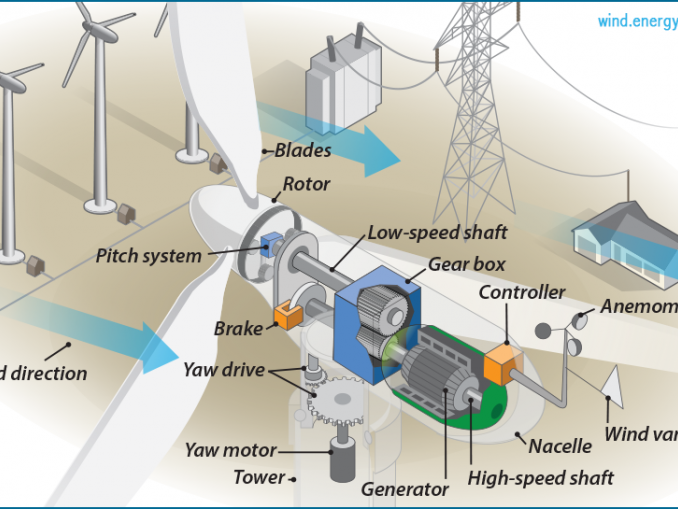

Wind turbines are simple machines. In addition to the long tower and the blades, a turbine’s basic components consist of a gearbox, a controller, a brake, a generator to produce electricity, a yaw drive and motor (used to keep the turbine facing into the wind), and low- and high-speed shafts.

An aerial drone equipped with thermal imaging equipment can detect these tell-tale heat signatures before a component breaks down entirely, causing the wind turbine to be out of commission for an extended period of time.

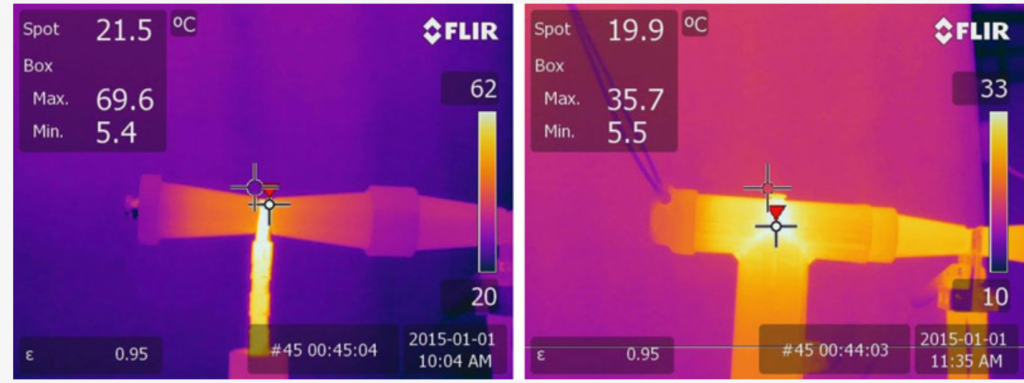

In the example below, a defect was purposely introduced into a dead break elbow termination of a wind turbine and then measured against that same termination with a shielding boot installed. The termination was subjected to 100 amperes of electric current for 15, 45, and 75 minutes and examined with thermal imaging equipment.

Thermal imaging can also be used to detect defects within turbine blades. The blades are made from composite materials and are subjected to stress during the manufacturing, transportation and operation. Cracks can develop in the blades, which can affect the efficiency of the turbine and lead to potentially dangerous accidents. Defects in the blade can change its thermal signature, which can be thermal imaging, even while the blades are in motion. Thermal imaging can detect possible defects, such as splits or internal problems, that wouldn’t register with a manual visual inspection.

The Benefits of Thermal Imaging for Turbine Preventative Maintenance

An offline turbine is a turbine that is not creating electricity. An average wind turbine can generate enough electricity in 94 minutes to power an average home in the United States for a month. Downtime for turbines can be costly and put strain on the rest of the power grid.

Thermal imaging for preventative maintenance of wind turbines can allow operators to repair or replace components before a failure occurs, while also detecting exactly where the problem is occurring. Over the course of its lifetime, operating and maintenance costs can make up 20 to 25 percent of the total cost of electricity produced by the turbine. Thermal imaging via aerial drone is quicker than manual inspection, requiring no direct contact with the turbine, while also scanning large areas.

The U.S. Federal Energy Regulatory Commission (FERC) predicts that renewable energy sources such as wind and solar generate 27 percent of the country’s electricity by 2023. Investing in preventative maintenance will allow renewable energy sources to scale more efficiently in the coming decades as the power grid continues to move away from fossil fuels.

Solar Cell Manufacturing meet Goals

Solar Cell Manufacturing meet Goals  Charting the Deep: Understanding Our Oceans, Envisioning Our Future

Charting the Deep: Understanding Our Oceans, Envisioning Our Future