Lidar makes its points at Europe’s dams

Terrestrial lidar scanners and sophisticated new mathematical models help engineers model dams to understand safety and risks

Europe has a lot of dams. While most were built after World War II, some of the continent’s 7,000 large dams can be traced back to the Roman Empire. They serve many purposes, protecting cities and farmland from flooding, and generating 13% percent of Europe’s electricity from hydropower.

Dams are also some of our biggest and potentially most dangerous civil engineering projects. It’s vital for engineers to generate highly accurate models of these structures for safety testing. What are the risks? When will dams need to be repaired or replaced?

In early days this meant physical scale models made of concrete, and many dams still exist that were originally designed according to these practical models. Most governments are now upgrading their old scale models with new mathematical models, often derived from terrestrial lidar scanners with the help of computers. These mathematical models describe the dams and their surrounding rock faces much more accurately and are also useful in determining how the dam and surrounding rock would interact during a seismic event, something for which the scale models could not always account.

A pandemic-shortened timeline

Such is the task that faces IMAGEO s.r.l. today. Dr. Andrea Tamburini, a world-renowned expert in geotechnical analysis, spun IMAGEO from the University of Turin in 2007 and made it into one of Europe’s leading survey companies for geomatic and geological surveying and analysis. This reputation helped IMAGEO secure part of a large government tender to survey several older dams. Many of these dams, originally designed in the 1950s to 1980s, were designed using the early scale model approach, so IMAGEO needed to execute some as-built surveys before they could create a new mathematical model.

Of course, no survey goes off without a hitch, and the dam project encountered a serious complication with the coming of the COVID-19 pandemic. IMAGEO had just completed its first two dams of 2020 by the middle of February when the pandemic ground much of society to a halt. With the resulting restrictions on travel and closure of hotels, IMAGEO had to stop their campaign for several months. Surveying only restarted in late May, cutting several months out of their schedule, so IMAGEO needed to do a whirlwind of work to cover the remaining 8 dams before time ran out at the end of 2020.

All the data that matters

The terms of the tender allowed each of the surveying companies some freedom in how they collected data from the dams. Some of the companies that won tenders for other dams decided to use traditional surveying methods, which involved a handful of field surveys on easily accessible rock near the crest of the dam. The downside of this approach is that they couldn’t survey the less-accessible parts of the gorge without climbing equipment. Instead, they used their limited tests at the crest to estimate the general properties of the rock around the dam.

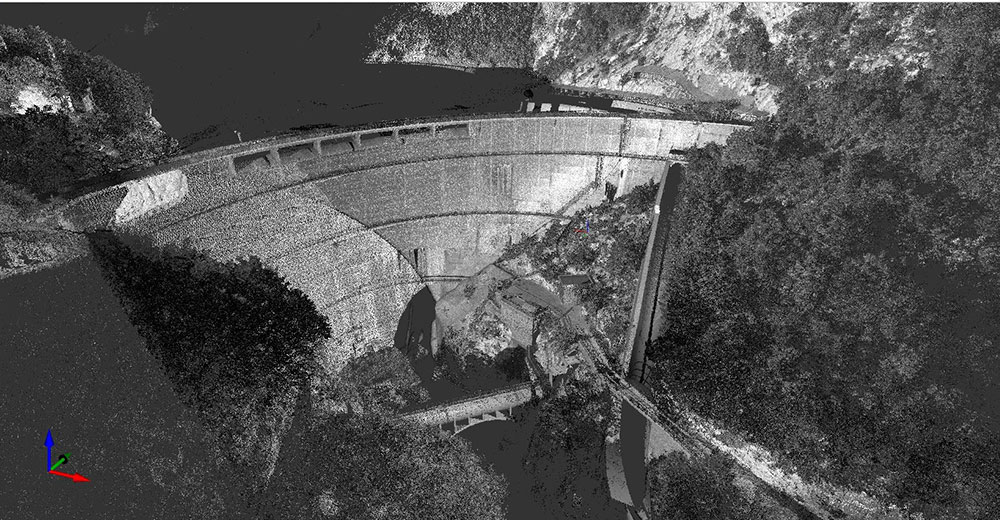

IMAGEO, however, decided to deploy its new Optech Polaris to help fill in the holes in its field surveys. This terrestrial laser scanner rapidly fires its laser at a target to measure range using a time-of-flight technique. The Polaris spreads these pulses out over a wide field of view using a 360° rotating base and a 120° scanner mirror, making a highly detailed 3D model of the entire dam’s morphology. This let IMAGEO easily survey an entire dam and its surrounding area, even the most difficult-to-access parts on the wall of the gorge, all from a safe vantage point.

Most of these surveys were done at ranges below 250 meters, which meant that the high maximum range of the Polaris (2000 m) was overkill for this particular project. Instead, IMAGEO took advantage of these short ranges to turn the Polaris up to its maximum pulse frequency of 500 kHz, letting it survey the dam section and rock face rapidly and in remarkable detail. In Dr. Tamburini’s experience, the point spacing must be 4 to 5 cm to perform a detailed geomechanical characterization of the rock face. At its maximum pulse rate, the Polaris easily achieved this point spacing with only a few minutes at each site.

Another time-saving feature of the Polaris was its 360° rotating base. IMAGEO’s earlier TLS systems had a limited horizontal field of view, so the operator often had to make multiple surveys from each survey point to capture a full panorama, manually rotating the system between each survey. Moreover, the operator also had to stitch together the data from these surveys during post-processing to create a single point cloud. The 360° FOV of the Polaris meant that IMAGEO could capture the entire panorama in a single survey, including real colors, saving time in the field and in the post-processing office.

This high survey speed was also useful because the morphology of the dam and surrounding rock did not always provide a clear target for surveying. Oftentimes their initial survey would have parts of the data obscured by outcroppings or other projections, so in these cases IMAGEO needed to capture the scene from multiple survey points to fill in all the gaps. The speed and minimal setup time of the Polaris meant that the addition of multiple points did not add too much time to the survey.

While the lidar was going on with one team, IMAGEO also collected additional field survey data with a second team. These included drilling boreholes in certain key areas of the rock and dam section to collect core samples and perform borehole televiewer (BHTV) logging. They also executed physical surveys, measured the roughness of the discontinuities, and checked for the presence of water. In total, IMAGEO managed to accomplish the full field and lidar survey within just 3 days per dam site.

Automated mapping of advanced deliverables

Back at the post-processing office, the task was to use all of these datasets to characterize the rock mass at all parts of the survey area. Much of this workflow is the product of Davide C. G. Martelli, IMAGEO’s rock mechanics expert, who took the standard rock mass rating formulas from the literature (e.g.: Hoek & Brown, 1997; Ulusay & Somnez, 1999; Cai & Kaiser, 2006; Bieniawski, 1976; Barton, 2002; Singh & Goel 1999) and used them to devise a standardized methodological approach to this characterization.

Considering the shortened timeframe and the large quantity of data produced by the Polaris, IMAGEO needed to automate this processing workflow as much as possible. After each survey, IMAGEO initially processed the Polaris data using its Optech ATLAScan software, automatically cleaning out the noise and vegetation to get the bare rock face. The software also allowed IMAGEO to merge multiple scan positions together using an automatic iterative closest point (ICP) workflow.

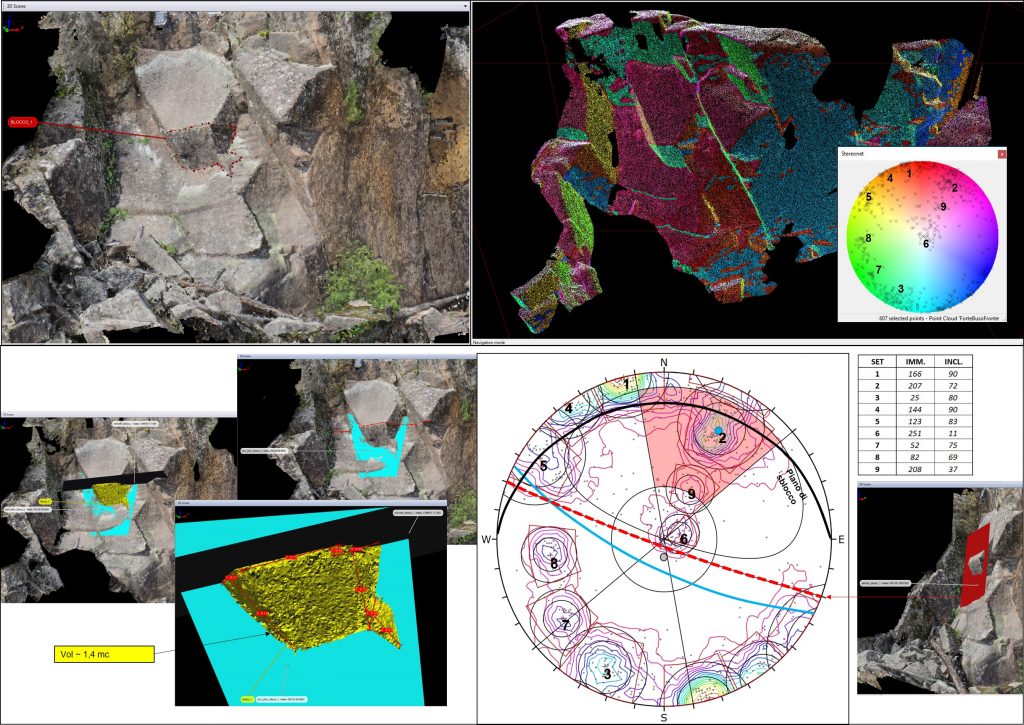

IMAGEO then imported the data into Coltop3D, specialized software from Terranum, a spin-off of the University of Lausanne. Designed to analyze the geometry of rock faces, Coltop3D automatically searched for and defined the discontinuity surfaces in the point cloud and assigned to each point the orientation of its surface.

To get a proper rock mass rating, IMAGEO needed to turn this geometrical analysis into more detailed information. However, few commercial tools exist to automate such specialized work. Instead, IMAGEO has devised their own algorithms in ArcGIS to map these parameters. These algorithms automatically map the fracture density per m2, the length of the actual traces, the average spacing for each discontinuity set, and the persistence (i.e., lateral continuity) of the discontinuities of the rock mass, greatly accelerating their post-processing workflow.

Finally, IMAGEO combined all of this data with the borehole data and field surveys to into standard rock mass rating formulas. This provided a full view of the rock mass rating and its contributing parameters over the entire survey area.

Due to the high level of automation in this process, IMAGEO could process the lidar point cloud rapidly, requiring only about 3 days per site. Combined with about 3 days actually surveying, that was a total of 6 days per site. With the lidar survey itself taking up so little time, IMAGEO could focus their work on integrating all of the lidar and field survey data together, including the conventional geological, geomorphological and geomechanical studies, borehole data (stratigraphy, BHTV, core analysis), lab tests and geophysical investigations from the physical survey. This final integration took up to a month of office and lab work per site, which was make for a tight deadline, but IMAGEO still expects to finish the final deliverables for their client by the original delivery date.

Compelling results

When IMAGEO sent the initial few datasets, the government modellers were highly impressed by the level of detail and the fact that the data covered the entire dam and surrounding rock face. Instead of a generalized characterization of the rock and dam produced by traditional methods, the modellers could see the rating of the rock masses in specific areas, letting them know which parts were prone to instability and needed repairs or reinforcement. The dam engineers could also use the laser scanner point cloud as geometrical input for their mathematical modelling.

The results were impressive enough that the government now requires the use of IMAGEO’s approach, leaving surveyors without a TLS scrambling so that they can continue to work on the dam projects. Such success indicates that terrestrial laser scanners and IMAGEO’s automated post-processing workflow are considered best practice for dam characterization and similar geomechanical surveys.